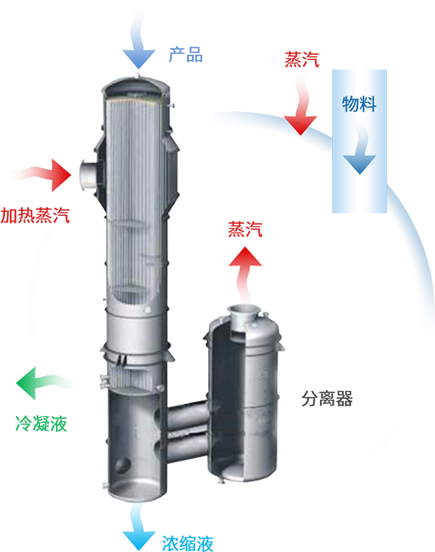

Most of the evaporators (reboilers) used in the petrochemical industry, pharmaceutical and water treatment plants adopt conventional evaporators (reboilers) with the disadvantage of low heat exchange efficiency and relatively high energy consumption. Compared with conventional equipment, WCE’s high-efficiency falling film evaporator (reboiler) can potentially reduce energy consumption by over 30%.

The Falling Film Evaporator features a large concentration ratio, wide viscosity range, very low to negligible pressure drop, excellent heat transfer coefficient, large treatment capacity etc. It is widely used in the petrochemical plants for production of glycol, ethanolamine, caprolactam, styrene, alkylphenol, acrylic fiber, polyester, chlor alkali, polycarbonate, and water treatment as well as in the light and food industry.

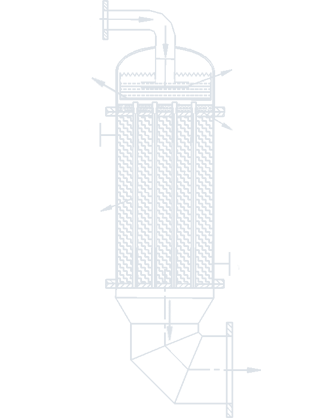

- A falling film evaporator is a vertical tubular heat exchanger. Under gravity, the fluid flows along and down the inner wall of the tube in a thin film to achieve evaporation and heat transfer.

- A liquid distribution device is positioned in the upper channel, consisting of a liquid distribution plate and film distributor at the heat exchange tube end opening.The liquid in the tube and the hot steam outside the tube both flow downward in a co-current direction.

- Due to the short event time, the heat sensitive materials are not degraded by the high coefficients.

- It is very important for the operation and efficiency of the equipment that the tube inner surface is fully wetted with the liquid.

鍵技術(shù)/p2-11071180034.jpg)

高低/001-14165815211.jpg)

高低/002-14170955808.jpg)

高低/003-14171881230.jpg)

高低/004-14172913091.jpg)

高低/005-14174184741.jpg)

鍵技術(shù)/p3-11071141896.jpg)